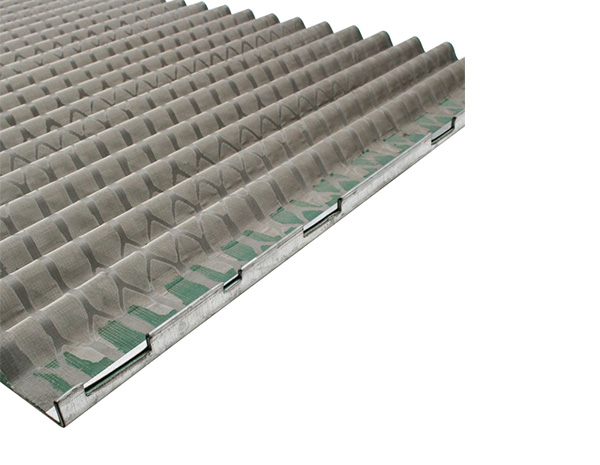

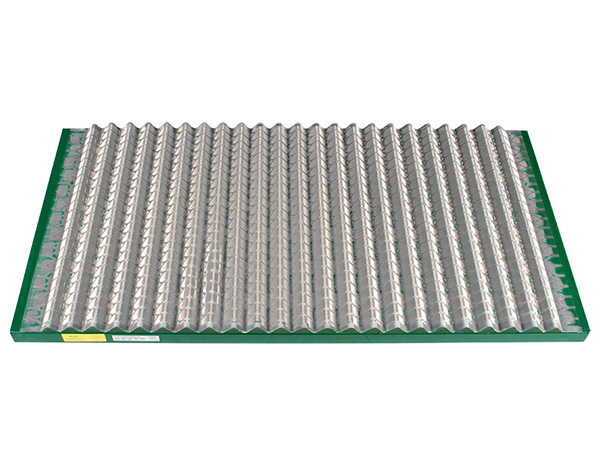

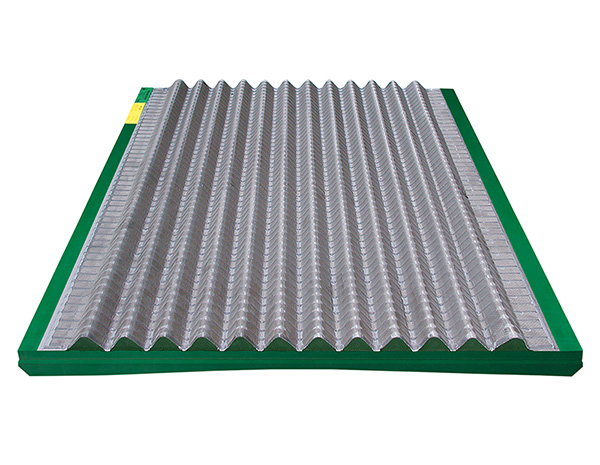

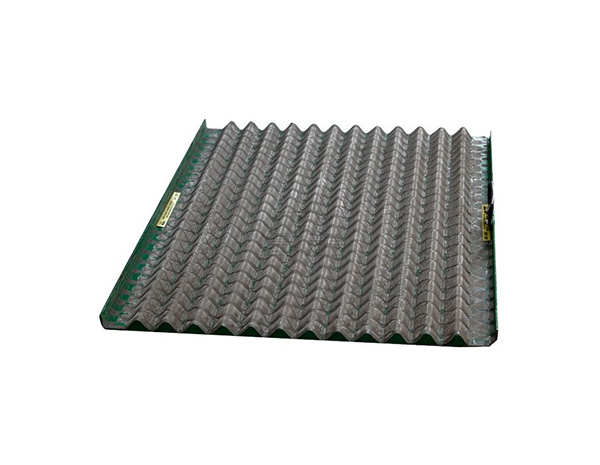

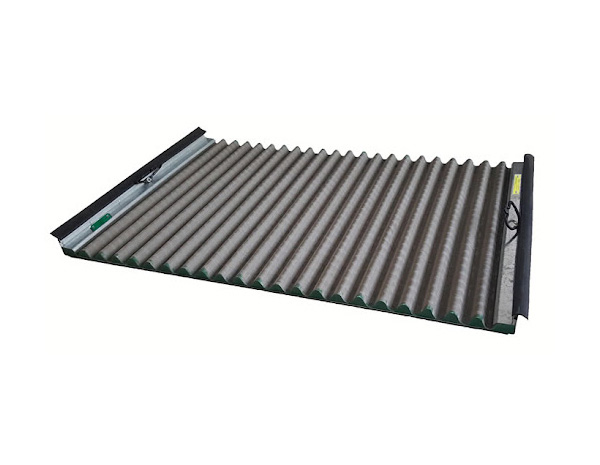

Corrugated Shaker Screen

These screen products are constructed with two or three layers of 304 or 316 stainless steel wire cloth after compounded and bended, and then combined with a steel backing plate. The wire cloth and bottom steel backing plate are combined tightly, which increases the filtering area up to 120% to 150% than that of hook strip flat screen and gets a better filtering effect.

Corrugated shaker screen is named by his special corrugated form. Its main features are as follows:

These screen products are constructed with two or three layers of 304 or 316 stainless steel wire cloth after compounded and bended, and then combined with a steel backing plate. The wire cloth and bottom steel backing plate are combined tightly, which increases the filtering area up to 120% to 150% than that of hook strip flat screen and gets a better filtering effect.

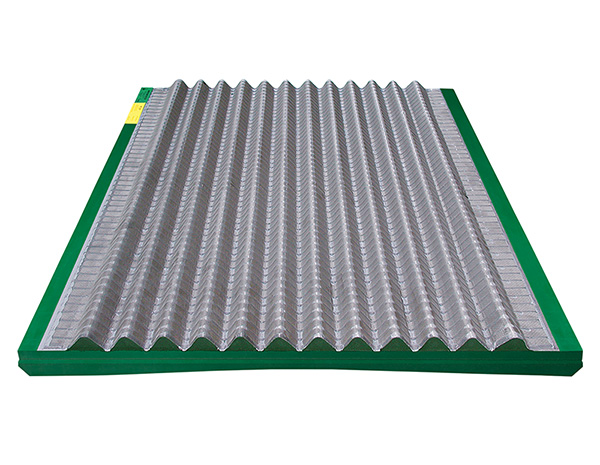

Features:

Screen Finer Faster – Utilizing Corrugated Shaker Screens enables rigs to screen 2 to 3 mesh sizes finer than with traditional flat panel screens without sacrificing capacity. This maximizes solids removal capabilities.

Makes Fine Separations – Corrugated Shaker Screens are capable of making separations as fine as 43 microns.

Fits Existing Shakers – There is no need to modify or replace existing equipment. Corrugated Shaker Screens fit all shakers, allowing the most efficient use of existing equipment.

Drier Cuttings – Corrugated Shaker Screens minimize fluid loss by spreading thinner layers of fluid over a relatively larger screen surface, offering more effective drying results.

Enhanced Permeability – Gravity and vibration forces the solids into the corrugated screen’s troughs, thus allowing more fluid to pass through the top of the screen.