Wire Cloth Screen Edge Hook Clamping Strips

Mar. 05, 2018

Clearance

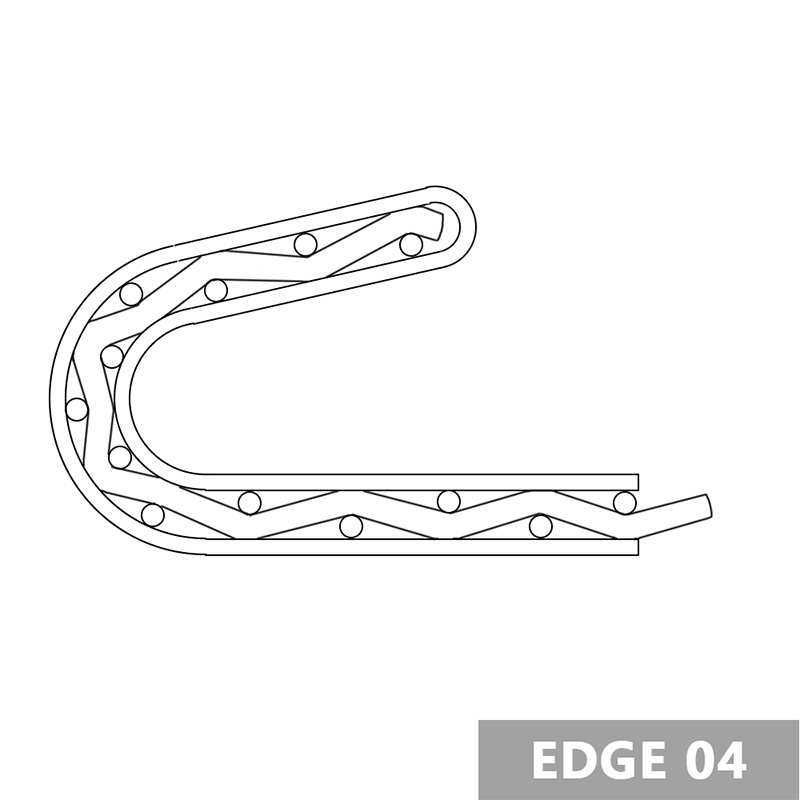

Approximately 40mm clearance should be allowed between the overall width of the screen cloth and the inside measurement of the screen box. This allows for 20mm on each side of the screen cloth for tensioning, and take up.

Sections

Where possible divide the full screening length into sections so that when one part of the screening surface wears out, only one part of the screening surface has to be replaced, thus reducing time, labor, and screen cloth costs.

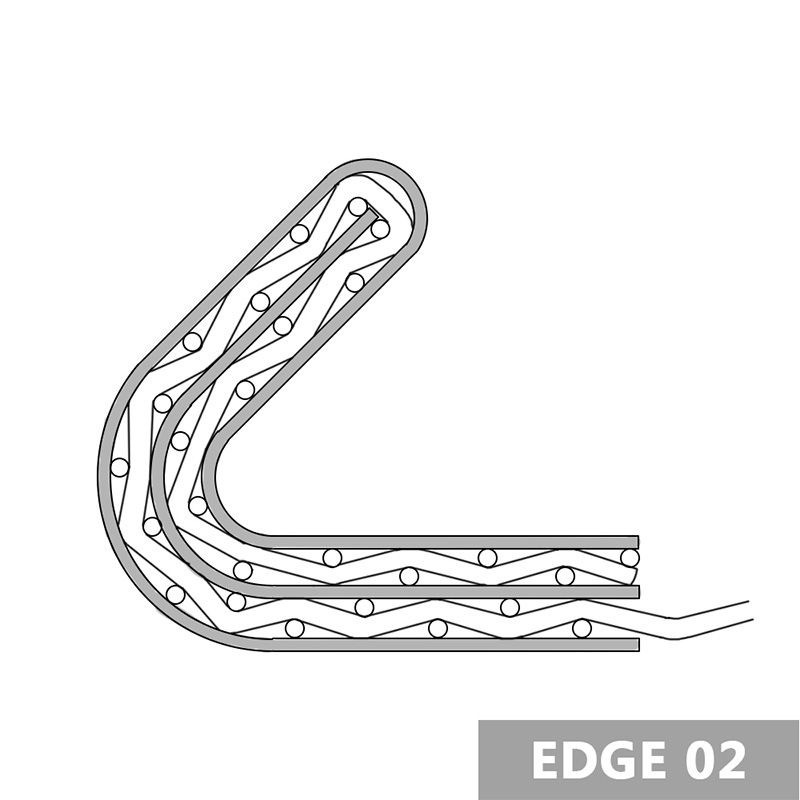

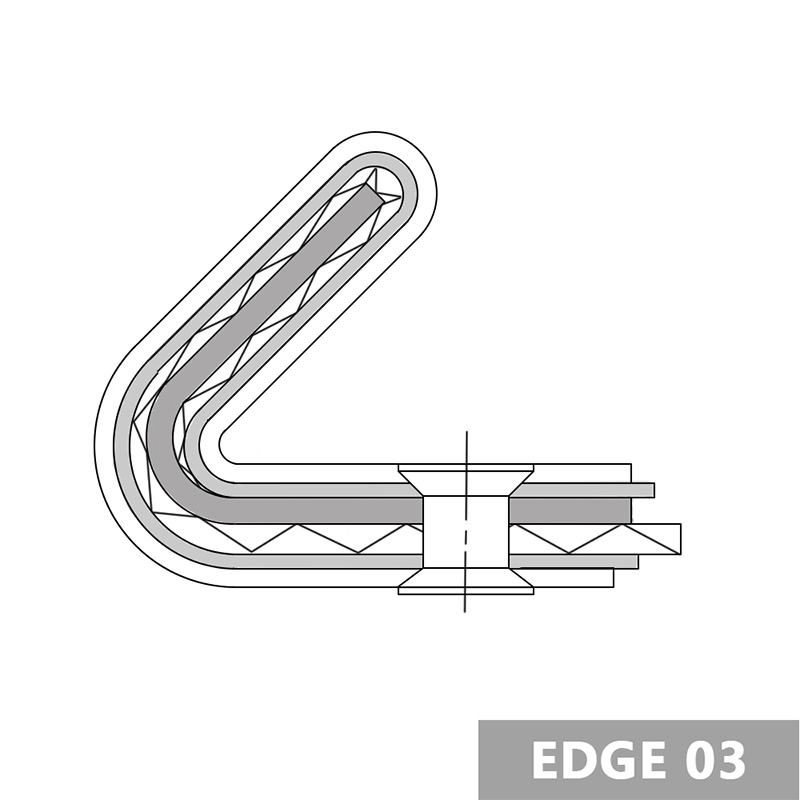

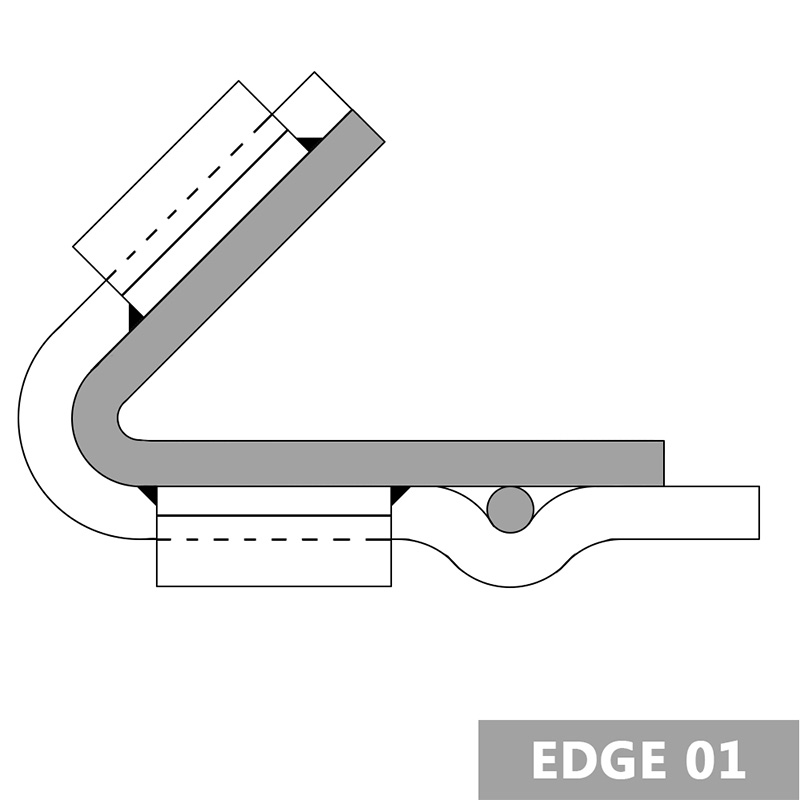

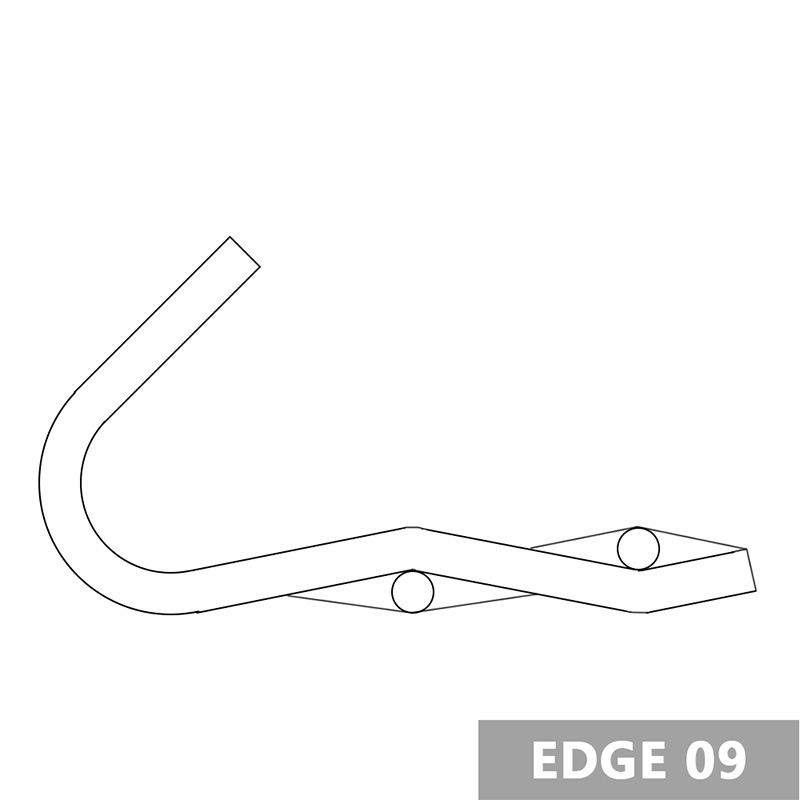

Clamping bars should be the same length as the section and fitted with the necessary number of wedge bolts, at approximately 300mm centres. Small aperture screen cloths should be 25mm longer and notched to allow screen cloths to overlap and prevent contamination.

Tension

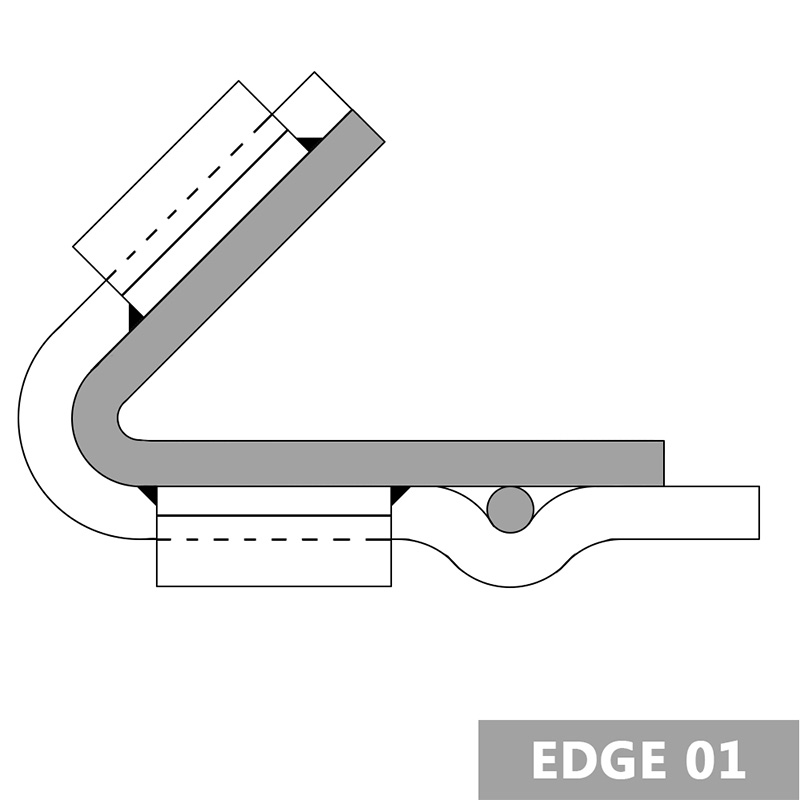

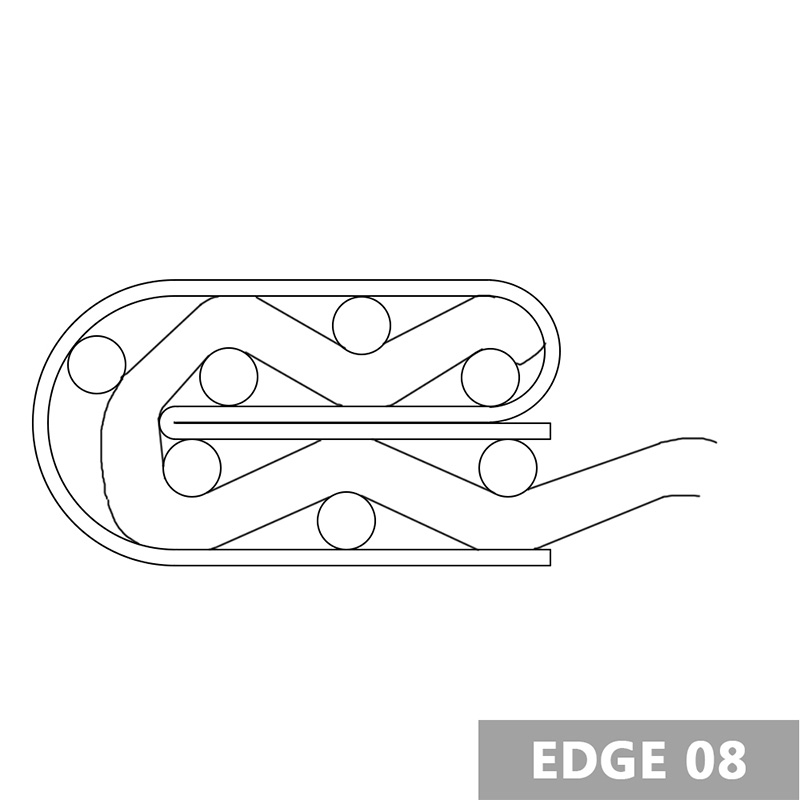

Before the screen cloths are fitted, check that stringer bars and rubbers are not worn, twisted or brittle. Make sure that the screen cloth edge is not jammed between clamping bar and bottom plate and can move easily, when

tension is applied. Do not allow the clamping bar to get caught between the sheet metal and the screen cloth.

Tension each side evenly starting at the centre and work outwards and re-check regularly.

Run screens empty for some minutes and re check for loose bolts\wedges, uneven tensioning and settling in of the.