- Home

- PRODUCTS

- Rubber Screens

- Piano Wire Screens

- Flip Flow Screens

- Shale Shaker Screen

- Corrugated Shaker Screen

- Hook Strip Flat Screen

- Hook Strip Soft Screen

- Manganese Steel Welded Screen

- Filtration Sand Control Screen

- Sieve Bends

- Scalp Shaker Screen

- Stainless Steel Mat Mesh

- Polyurethane Rod Screen

- Polyurethane Edge Screen Plate

- Polyurethane Self-cleaning Mesh

- Flat Top Screen

- Lock Crimp

- Double Crimped

- Self-Cleaning Screen Mesh

- Rectangular Screen

- Long Slot Screen

- Under Ground Supporting Mesh

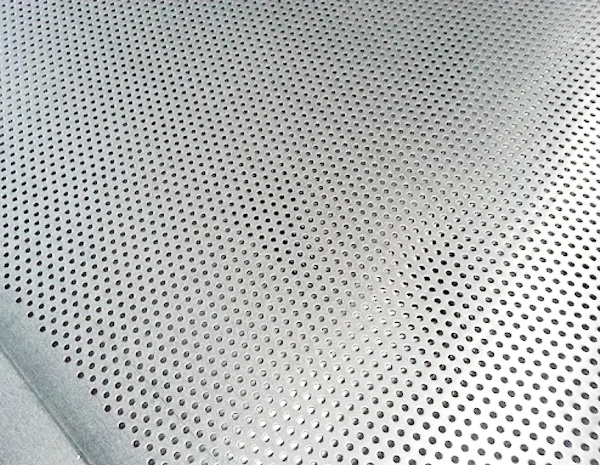

- Heavy Perforated Mesh

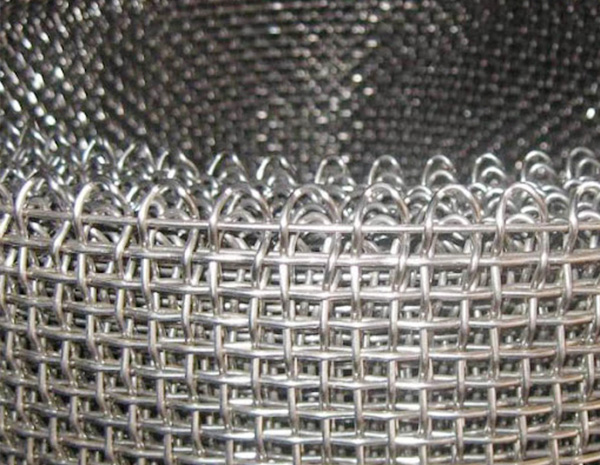

- Stainless Steel Mesh

- Wedge Wire Screen

- Trommel Screen Mesh

- Polyurethane Screen

- NEWS

- ABOUT US

- FAQ

- CONTACT US