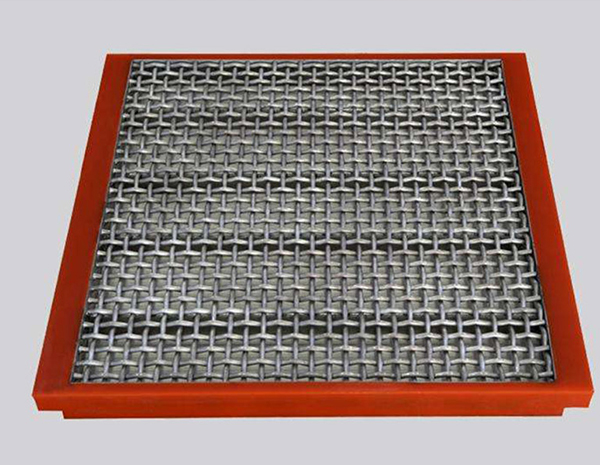

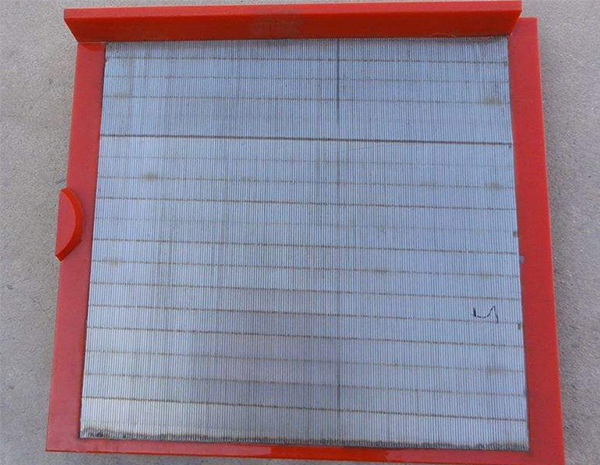

Polyurethane Edge Screen Plate

Polyurethane-bound slit screen plates are also known as slit screen plates, dewatering screen plates, vibration modules, etc. They are usually installed on various linear screens, high-frequency screens, and banana screens for use. They play the role of dehydration, desludging, de-intermediation, and grading. High-quality polyurethane-bound slit screen plates usually consist of three parts.

Polyurethane-bound slit screen plates are also known as slit screen plates, dewatering screen plates, vibration modules, etc. They are usually installed on various linear screens, high-frequency screens, and banana screens for use. They play the role of dehydration, desludging, de-intermediation, and grading. High-quality polyurethane-bound slit screen plates usually consist of three parts.

The first part: stainless steel welded slit screen. The screen is welded from high-quality stainless steel trapezoidal wires. The trapezoidal wires have high strength and high wear resistance, and the screen seams are welded firmly. The screen seams are narrow at the top and wide at the bottom, and will not be blocked by the maximum size of the material. The dehydration effect is far superior to other dehydration screens on the market, and can effectively increase the purity of clean coal by 2%-3%. The trapezoidal structure of the screen wire allows the screen to be used for a longer time without damage.

Part 2: Q235 flat iron skeleton structure. The flat iron skeleton ensures the flatness of the screen surface during welding, effectively supports the screen surface, and the screen surface is flat, and the material passes evenly. The advanced welding process and reasonable support structure will not cause the screen to break and wire to break due to metal fatigue deformation and desoldering.

Part 3: Glue frame. The linear screen plate frame can be edged with polyurethane or wear-resistant rubber. The edge structure can effectively reduce production noise, increase the service life of the screen plate, and slow down the fatigue rate of the metal. The screen plate is installed in the mold for polyurethane and rubber casting and edge wrapping. The size of the formed screen plate is more accurate. After installation, the screen plate is tight and will not leak coal or fall off. The rubber-coated structure is faster when the screen plate is replaced. By combining and installing with various rubber-mounted accessories, a single screen plate can be replaced separately if it is damaged, without affecting the overall screen surface.