As an ISO Certified Company, YHY screens are manufactured using the highest quality of materials to ensure a high wear resistance, rubber screens are available and manufactured in a variety of thicknesses and hole sizes to meet customers requirements and offer optimum performance.

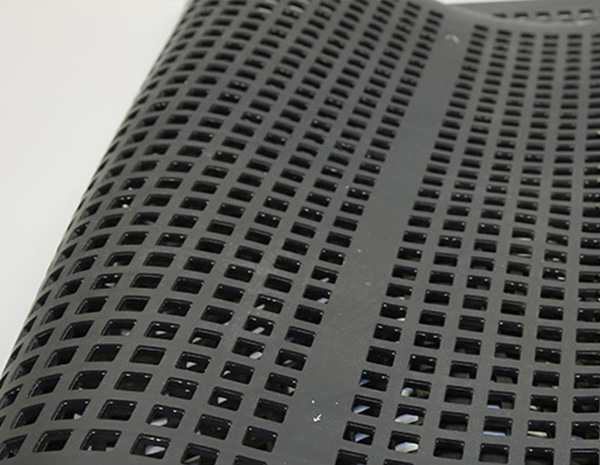

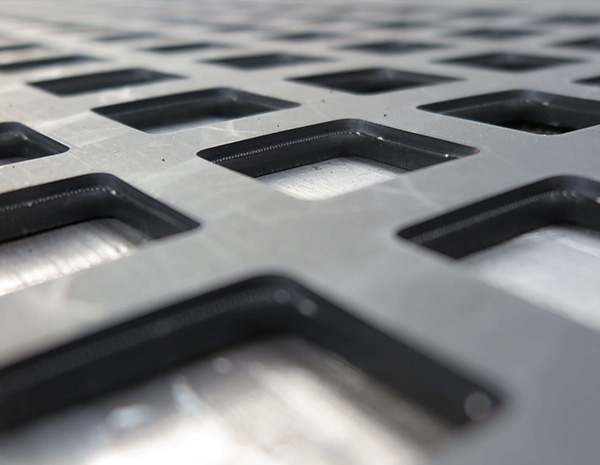

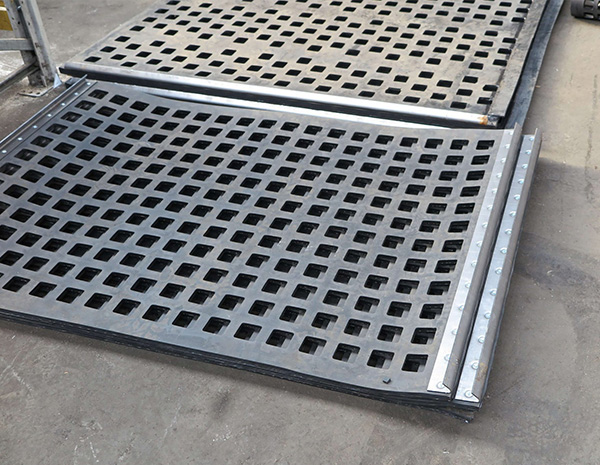

Rubber screens can be adapted to suit almost all makes of machinery. Rubber screens offer many advantages including longer life span and reduced noise levels. They are particularly suited to the upper part of screen decks, or on a complete deck, where required. YHY manufacture perforated rubber in 3mm up to 35mm thick material as standard but rubber screens can be manufactured in thicker material ranging up to 50mm in thickness. A variety of apertures are available from 3mm to 150mm and can be perforated using different shapes such as round holes, square holes and slotted holes on rubber screens, this is done to suit the different types of grading required. Rubber screens have a lower open area than wire mesh, especially on smaller apertures.

ADVANTAGES OF RUBBER SCREENS

Screens are noise reducing, creating an improved working environment for personnel

Rubber screens are manufactured in natural SAR Grade rubber with a shore hardness of 65, which offers excellent resistance to impact abrasion

Screens can be manufactured by YHY to suit almost all makes of machinery within the quarrying, waste management and recycling industries

They do not suffer from pitting or stress corrosion, particularly in the presence of seawater

TECHNICAL DETAILS

YHY advanced machinery offers an impressive cutting force of 40 tons, and cutting strokes of 110mm

The maximum screen size available is 4m x 2m

The maximum material thickness 50mm

Percentage open area varies from 35% to 45%

Grade Quality: screens can be manufactured with a shore hardness to suit your requirements